Overview

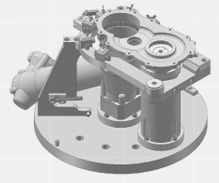

JEP Precision Engineering strives on a fully-equipped production facility, comprising of the latest technology in CNC machines and CAD/CAM for product design and manufacturing. Our machine inventory consists of a variety of machines from CNC 5-axis milling, vertical and horizontal milling, vertical and horizontal lathe to cylindrical and surface grinding machines which enables us to design and efficiently manufacture parts with precision. We have an extensive experience in machining Inconel, titanium, stainless steel, aluminum, and iron castings parts. We specialize in machining highly complex, thin walled and large format parts that consist of intricate bosses and profiles in production quantities.

We are progressively investing in our team of engineers as well as design softwares to provide a seamless work flow with clients. Our engineers are proficient in and are currently working with Unigraphics, Solidworks & CATIA.